Dairy

OZONE in Dairy Processing:

Ozone treatment is the most efficient, cost-effective and eco-friendly food-processing technology. It is successfully used globally, for the removal of milk residues and biofilm-forming

bacteria from stainless steel surfaces and in milk processing, including fluid milk, powdered milk products and cheese. Ozonation has been shown to prevent mould growth on cheese and

inactivate airborne moulds in cheese ripening and storage facilities. Ozone treatment has also been found to be a promising method for reducing the concentrations of pollutants in dairy wastewaters.

Our systems provide the following distinct services essential for the Dairy Industry:

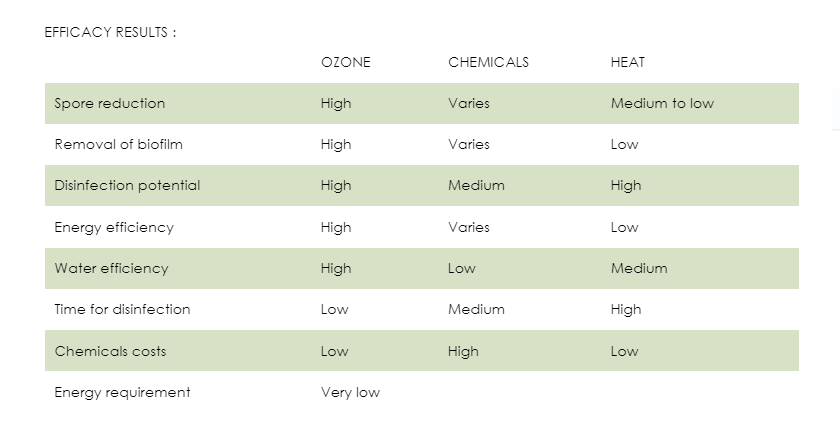

- Clean-In-Place (CIP) : For disinfecting the equipments used in processing, hot water with chemicals is generally used, consuming a large amount of energy and chemicals.

The use of ozone considerably lowers chemical costs and completely eliminate hot water costs on dairy farms. - Clean & disinfect the animals : If the hind legs, udder and teats of cows are thoroughly washed off with ozonated water prior to milking, many hygienic problems may easily be prevented.

- Sterilizing Fluid Milk : Heating negatively influences both the nutritional value and the sensory properties of milk. For this reason, mild ozone treatment of liquids, including milk

and fluid dairy foods is practised, thereby minimising their possible quality deterioration. Pressurised ozone treatment reduces the number of psychrotrophs by more than 99%. Complete

elimination of Listeria monocytogenes from both raw and branded milk samples through ozonation is possible. - Fumigation of Milk Powders : Pathogenic contamination in powdered food products is absolutely denatured by ozone fumigation process - treating them with dry gaseous ozone from the bottom

of their storage silo. - Wastewater treatment : Ozonization of wastewater / effluent water nullifies all harmful contamination with BOD, COD, pathogens, etc. The water is completely de-odourized and de-colourized.

This water after ozone treatment, can be re-used for various purposes, including processing & irrigation.

Plus, Ozonated ETP & STP with pre-treatment Ozonation - that saves 40% of capital cost & 50% space!